Custom vs Standard IC Chips: Making the Right Choice

Custom vs. Standard IC Chips: Making the Right Choice

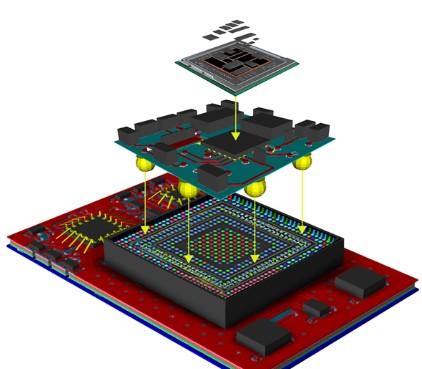

Image source Quora

In the electronics arena, there are different ways of classifying integrated circuits. One way is in their make whereby we can classify them as standard integrated circuits and custom integrated circuits. Since ICs are at the heart of every electronic device and appliance, it is important to know the differences between these two types of ICs.

You can easily tell the difference between custom ICs and standard ICs. Standard semiconductor chips come in their original form from the manufacturers. They are usually mass-produced to be used in their designated application areas. On the other hand, custom ICs are specially designed and customized to be used in specific application areas where they will perform specific functions.

There is more to that than their definition. In this article, we are going to have an in-depth discussion on the differences between standard integrated circuits and custom integrated circuits. At the end of it all, you will be in a perfect position to choose the right semiconductor chip for your business.

What is a standard IC?

The name itself is self-explanatory. Standard integrated circuits are the ones that are produced in large quantities by manufacturers and are used for executing generic functions. There is nothing unique or special about these semiconductor chips. All you need is to buy them and integrate them into your application in their original form.

Since these ICs are mass-produced, you can easily buy them in bulk. However, you will still need to know the specific functions and applications of the standard ICs before buying. Some are used for power regulation, control, and data storage among many other functions. Furthermore, standard ICs are widely available and you can easily find them from different distributors around the world. Additionally, placing orders or custom ICs is quite an easy process. You don’t have to get into deeper details about the product. Simply define the name and some specifications of the chip and you will have your orders fulfilled.

Properties of standard ICs

Some of the key properties of standard ICs include but are not limited to the following:

· Wide range of applications: Standard integrated circuits are designed to meet the needs of a large market. This means that they can be used for different application areas. They are quite versatile such that they can easily fit into different industries without the need for any modifications.

· Highly compatible: The versatility of standard ICs means that they can be easily integrated into different solutions. This is possible because these integrated circuits come with standard features such as connections and pins.

· Mass production: The standardization makes it easy for manufacturers to produce standard ICs in bulk. This helps to lower the prices of these ICs.

Defining custom integrated circuits

Unlike standard ICs, custom ICs are more application-specific. This means that each IC is designed to meet specific application needs. A manufacturer will produce this semiconductor chip while having a particular application in mind. This is unlike standard ICs which are produced to be used in a wide range of applications.

Custom integrated circuits are tailor-made from scratch to be used in specific application areas. They come in different sizes, shapes, and designs. They tend to have superior features than the standard chips. For instance, they deliver superior performance than the standard chips. Of course, some disadvantages come with custom ICs and we will look into them.

What does customization entail?

There are different features of integrated circuits that are customized to meet the needs of specific applications.

· Physical design: The physical layout of the integrated circuit is customized. The process entails changing the size, shape, and other physical dimensions of the IC. This is done to ensure that the IC fits into a particular area

· Circuit or logic design: Here, the blocks that make up electric circuits in an IC are customized so that you can achieve the desired goal. The customization may achieve better performance or even functionality of the IC

· Architectural design: The functionality of the integrated circuit is designed and customized according to the needs of an application. It also focuses on the performance parameters of the IC such as speed, power consumption, and memory capacity among others.

Table comparing standard ICs vs. Custom ICs

The table below gives a summary of the comparison between standard integrated circuits and custom integrated circuits.

Area of difference | Standard IC | Custom Ic |

Manufacturing process | They are manufactured using the general standard procedures of chip production. Mass production is used to produce the chips | Manufactured using special and customized manufacturing procedures. The process entails deep collaborations between the users and the manufacturers to get everything right |

Functionality | These chips are designed to perform general functions in electronic applications | Designed to perform specific functions in electric applications |

Design and build | Feature general designs that are similar to many other integrated circuits depending on the functions. | Feature unique designs that are suitable for specific application areas. |

Availability | Easily available from different distributors. You can easily place your orders and the chips will be delivered within a short time. | Not easily and readily available. In most cases, customized ICs can only be availed at a special request. You need to place an order before the product is availed. Also, very few distributors stock custom chips. |

Performance | They generally perform well depending on the specifications of the IC. However, their performance may not be as good as that of custom ICs | Custom ICs are designed to deliver superior performance than standard ICs. Performance is one of the reasons why an IC is customized. |

Cost | Standard ICs are generally cheaper than customized ICs. Their prices depend on their features and manufacturers | Custom ICs are more expensive than standard ICs. It takes lots of effort and price to customize an integrated circuit. The price will depend on the features of the customized chip |

Flexibility | Standard integrated circuits are rigid and offer minimum flexibility. You cannot change the design and features of the chips | Custom ICs are highly flexible. They can be customized to meet the needs of specific users. They are also scalable as you can improve the performance and functionality of the chips |

Application | Have a wide range of applications | Are designed for specific applications. |

Which one should I choose? Custom vs standard

After doing a comprehensive comparison of the custom vs standard integrated circuits, there will come a time when you will be required to choose one. There are several factors that you should consider when it comes to choosing either custom or standard integrated circuits.

· Application requirements: What kind of electronic application are you building? This will determine the type of IC chip that you should buy. If it is a general-purpose application, then you will go for standard integrated circuits. Does your project have any unique features and requirements? Custom IC chips may be more suitable for such projects.

· Performance: What kind of performance would you like to see on your product? Custom integrated circuits are known for delivering superior performance than the standard ICs. Otherwise, I you are not keen on performance, you should consider settling for the standard IC.

· Cost/ Budget: How much are you willing to pay for the integrated circuits? From the comparisons that we have done, it is clear that custom ICs are more expensive than the standard ICs. However, do not let the cost factor make you ignore other vital aspects such as performance and compatibility.

· Availability: One feature of custom integrated circuits is they are not easily available. Very few suppliers and distributors stock them. So, if you want an easily available semiconductor chip, you should go for the standard ICs.

· Time factor: You should also consider the available time. It will take you longer to order custom ICs. First, you will have to send your requirements to IC manufacturers so that they produce IC chips that meet your needs. This is different for standard ICs where you simply need to buy and use.

Once you consider all these factors, you will have a better chance of buying the right integrated circuits for your project.

Conclusion

The IC industry is quite dynamic and the best way to survive is by having the right information about all the products. I hope that with this article, you are fully equipped to understand the differences between custom ICs and standard ICs. I hope that now you can choose the best one for your business. You must explore all the possibilities before choosing the right integrated circuit.

So, where can I find the best standard IC or even custom ICs? The surest source is from reliable IC suppliers and distributors. A good distributor should stock all types of integrated circuits that you need. This way, you will be able to decide whether you want a custom IC or a standard IC.

At Rantle East Electronic, we stock both custom and standard integrated circuits. We are a reliable semiconductor chip distributor that is fully committed to exceeding the needs of our clients. Contact us directly whether you want custom ICs or standard ICs.

Kevin Chen

Founder / Writer at Rantle East Electronic Trading Co.,Limited

I am Kevin Chen, I graduated from University of Electronic Science and Technology of China in 2000. I am an electrical and electronic engineer with 23 years of experience, in charge of writting content for ICRFQ. I am willing use my experiences to create reliable and necessary electronic information to help our readers. We welcome readers to engage with us on various topics related to electronics such as IC chips, Diode, Transistor, Module, Relay, opticalcoupler, Connectors etc. Please feel free to share your thoughts and questions on these subjects with us. We look forward to hearing from you!

Start With

Start With Include With

Include With