The Future of Nanotechnology in IC Chip Fabrication

The Future of Nanotechnology in IC Chip Fabrication

Image source: Quora

Integrated chip fabrication entails all the processes and activities of fabricating semiconductor chips into functional products. The procedure is also known as microfabrication. Technically the process entails bringing together several semiconductor components, both passive and active components together to form a single complete chip.

The fact that electronic devices are increasingly becoming smaller means that semiconductor chips are also required to be smaller than usual. According to Moore’s law even as the devices get smaller, they will still have higher transistors. This is where the essence of nanotechnology comes in. The chip fabrication technology is expected to be in line with miniaturized devices. For this to be successful, nanotechnology should be fully embraced in the chip fabrication process.

Chip fabrication that is based on nanotechnology is expected to enhance the performance of the microchips. It should also achieve a higher packing density to enhance the functionality of the chip. Better chip performance will open a new world of possibilities. Other than performance, this technology is also expected to increase the reliability of the chips regardless of their application areas. Keep reading as we try to understand the future of nanotechnology in IC chip fabrication.

Need for better computing power

The computing power of microchips has always been on an upward trajectory. The fact that we have not reached the limit means that there is still room for better performance. Semiconductor chips should not only support speed but also have high data capacity. This can only be achieved with better chip fabrication technology. Nanotechnology should be able to achieve nanoscale chip size without compromising on the performance. This can be done through the proper implementation of the nanotechnology.

Fabrication challenges caused by nanotechnology

Even though nanotechnology for IC fabrication has a brighter future, some serious challenges are associated with the deployment of this technology.

First, the constant shrinking of the MOSFET geometry so that it can fit the nanometer scale is quite difficult. This is mostly because some leakage mechanisms that are deployed such as dielectric tunneling tend to cause logical failure on semiconductor chips.

Another challenge that is associated with this technology is speed. Silicon, the main material for semiconductor chips has an intrinsic speed limit. It may be quite difficult for nanotechnology to go beyond this speed during the IC fabrication process. Perhaps the most ideal option will be to go for alternative materials such as germanium, which also have their limitations.

Nanotechnology for IC fabrication makes it difficult for the power dissipation to be scaled down. This is mainly because the field-effect operation is powered by the mass flow of electrons. Fabricating millions of transistors into a smaller space will likely generate a significant amount of heat. This makes it necessary to downscale.

While the limitations tend to be a major hindrance, there is some hope for the future. The advancement of nanotechnology is geared toward addressing most of these limitations. We hope that shortly, there will be minimum barriers to the use of this technology in semiconductor chip fabrication.

Areas of focus nanotechnology chip fabrication

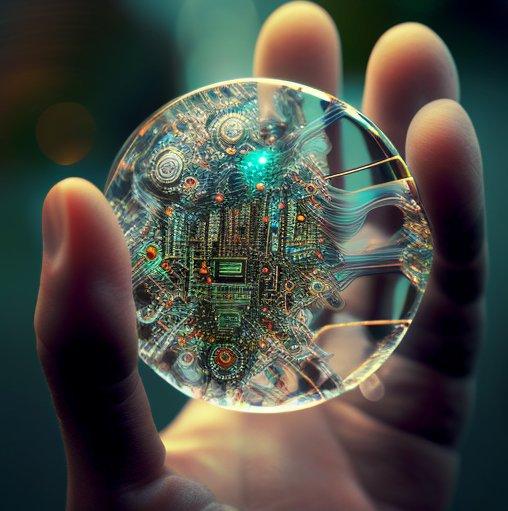

Image source Phys.org

Different areas of chip fabrication are expected to be affected by nanotechnology. They include the following:

Miniaturization

Based on Moore’s law, nanotechnology for chip fabrication is expected to preserve the trend of miniaturization. Semiconductor components will keep getting smaller over the years. One of the goals of nanotechnology is to ensure that components reach the nanoscale sizes. This applies to both passive and active components.

With miniaturization, it means manufacturers will be able to achieve high component density. Many components will be able to fit into a small surface area. Even as the technology sticks to miniaturization, it should not affect the performance and reliability of the semiconductor chips.

Self-assembly of nanostructures

This is another key feature of nanotechnology in IC fabrication. It is a completely nonlithographic process that is characterized by self-assembly and chemical synthesis. These nanostructures feature structural complexity that will always be determined by the nature of the chemical synthesis approach that is used. This implies that the nanostructure components are made of chemicals synthesized in labs. The chemicals have unique compositions that give them a unique set of chemical properties.

Extended CMOS computing

While the traditional chip fabrication features CMOS computing, it gets deeper when we use nanotechnology. It goes a mile beyond CMOS. Currently, the CMOS technology is almost reaching its limits in terms of physical size. They are getting smaller. This poses the challenge of overheating and power dissipation. With nanotechnology, the fabrication gets deeper into CMOS and even explores alternatives to the legacy CMOS. Technologies such as quantum computing are proving to be alternatives to the CMOS technology. Furthermore, they tend to bring out the best results from the CMOS technology by suppressing some of the limitations.

Sub-lithographic patterning

For years photolithography has been at the center of the IC fabrication process. It is used for defining patterns that electric circuits should take in semiconductor chips. The process entails exposing wafers to ultraviolet light rays.

In nanotechnology, nanoscale transistors and nanowires are used for defining the paths of electric circuits. For this reason, they are touted to be the future of IC fabrication. Nanowires are small and dense hence can function effectively when it comes to drawing paths for electric circuits. Also, the use of nanotechnology will get rid of the oxide layers that have been used in ICs for quite a long period. Furthermore, we cannot ignore the space-saving property of sub-lithographic patterning in semiconductor chip fabrication.

Molecular hybrid semiconductor chips

This is another anticipated impact of nanotechnology in semiconductor chip fabrication. The technology is expected to fully embrace the use of organic molecules in the chip fabrication process. Several advantages come with using organic molecules. They are super-dense hence making it easy to achieve miniaturization during chip fabrication. Organic molecules are uniform, both physically and structurally. Other than performance, these molecules have low power dissipation. Additionally, they can serve as passive and active components in electric circuits. Legacy materials are also expected to be used together with the organic molecules to achieve the best results.

Motivating factors for nanotechnology in IC fabrication

Even as we anticipate a brighter future of nanotechnology in semiconductor chip fabrication, some factors are likely to influence the rate at which this technology will be embraced. Here are some of the key factors:

· Cost of fabrication: The cost of fabricating integrated circuits will determine the rate at which manufacturers will embrace this technology. Fabricating IC chips using nanotechnology should be comparatively lower than using silicon CMOS. Since these manufacturers are in the business, they will not resist a technology that makes business sense.

· Degree of integration: As a method of fabrication, nanotechnology tends to provide a higher degree of integration. To be precise, it is higher than 1000 higher than that of the normal silicon fabrication. This allows more transistors to be fabricated within a small surface area. At the end of it, you will be able to attain a high component density.

· High current drive: It is easier to achieve a high current drive through integrated circuits that have been fabricated by nanotechnology. This high drive is relevant in driving the capacitance of interconnects in electric circuits.

· Excellent reliability: ICs produced through nanotechnology fabrication should prove to be highly reliable. They should be able to function in their designated application areas without any serious challenges. The chips should also have a longer lifespan.

· Low power dissipation: Nanotechnology should produce semiconductor chips that have low power dissipation. This way, you will not have to worry about heat management and as well as energy management properties of semiconductor chips that you are producing.

· High reproducibility: Nanotechnology should encourage mass production of semiconductor chips. One advantage of high reproducibility is it lowers the cost of production yet you will still be able to get a large volume of semiconductor chips being produced.

As long as the nanotechnology stays in line with the pointers above, then we should expect it to dominate the IC fabrication industry shortly. There are high hopes that nanotechnology will bring about critical solutions that are considered the drivers of the semiconductor industry.

Conclusion

Nanotechnology is expected to define the future of IC fabrication. It has the full potential of opening up the IC chip industry and the electronic industry as a whole. We expect to start seeing disruptive solutions that have been created by this chip fabrication technology. Even though it may still be in its infancy stage, it is progressively replacing the alternative silicon CMOS technology.

As someone who is building electronic devices, you should have high expectations for this technology. Maybe it will be a gateway that will open your path to better products. Meanwhile, in case you would like to buy IC chips that have been well fabricated, we have the right solutions. At Rantle East Electronic, we source chips from the best IC manufacturers. We test them to ensure that they have been properly fabricated and meet the required industry standards. You should consider contacting us for the premium-grade semiconductor chips.

Kevin Chen

Founder / Writer at Rantle East Electronic Trading Co.,Limited

I am Kevin Chen, I graduated from University of Electronic Science and Technology of China in 2000. I am an electrical and electronic engineer with 23 years of experience, in charge of writting content for ICRFQ. I am willing use my experiences to create reliable and necessary electronic information to help our readers. We welcome readers to engage with us on various topics related to electronics such as IC chips, Diode, Transistor, Module, Relay, opticalcoupler, Connectors etc. Please feel free to share your thoughts and questions on these subjects with us. We look forward to hearing from you!

Start With

Start With Include With

Include With